Book Appointment Now

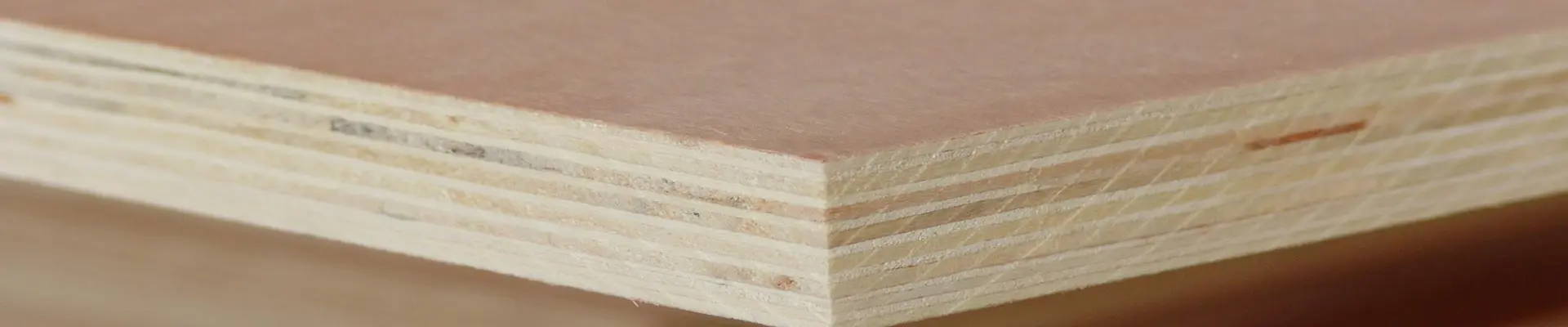

Marine Plywood

9/12/18/21mm marine Plywood

Brand:

Top Woods

Moisture:

7%-14% at the time of shipment.

Weight:

520-550kg/cbm

Packing:

Film wrapper, Plywood,/Carton, Steel band,18 pallets/40 HQ

Usage:

Construction/Furniture/Marine

Available in:

EXW, FOB, CNF, CIF

Minimum Order Quantity:

1*40HC

Lead Time:

10-20 calendar days on receipt of deposit

Product Specification

Thickness

5-28

Sheets/pallet

Depending on the thickness

Width

1220mm/1232mm/1247mm

Length

1830mm/1842mm/2135mm/2440mm/2500mm/2452mm/2464mm/2745mm

Grade

B/BB, S/BB, BB/BB, BB/CP, CP/CP, CP/C 1/2 Grade Lamination grade is available

Core

Mahogany/Eucalyptus/Combi/Okoume core

Glue

Melamine/Phenolic/WBP

Veneer

Okoume Veneer, 0.2mm/0.9mm

Marine Board. Ocean board is defined as BS1088 marine plywood international standard production, environmental protection up to E0/E1 class, boiling water 72 hours do not open glue, generally used in yachts, carts, ships, exterior buildings, also known as “waterproof plywood”, “marine plywood”.

Product feature:

1. The marine board is produced in strict accordance with the international standard of BS1088 marine plywood.

2. The marine board has excellent weather resistance and can be boiled for 72 hours without boiling.

3. The marine board adopts Taier waterproof glue (phenolic glue) to meet the environmental protection F4 star standard.

4. The weather resistance of marine board products has passed the authoritative inspection of the National Quality Supervision and Inspection Center for Wood-based Panels and Wood Bamboo Products.

Application:

1. Shipbuilding industry; car body manufacturing; docks, ports and other offshore buildings.

2. High-grade furniture production, wood floor substrate, wooden floor mat.

3. Outdoor outdoor stage, large-scale exhibition decoration project, various construction and decoration projects.

4.Outdoor wooden structure, wooden structure house, villa wall and floor, outdoor garden furniture.

Products images :

Details Images

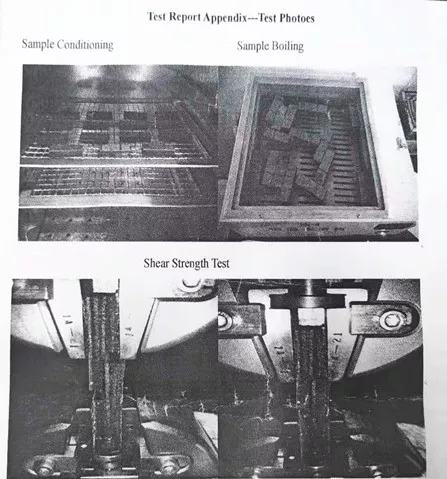

Our customers had do Bonding properties test for our marine plywood according BS1088-1-2003 test standard.

One of Test report description:

Sample specimens were glued with phenol Formaldehyde adhesive and no defects such as knot, split, color variation and decay are found within the sample specimens upon delivery. This kind of Marine Plywood usually used as standard Marine Plywood. Test Including sample’s Moisture content, Density, and bonding properties( Prepare ten pcs of sample specimens on basis of requirements stated in Section 3.2 of BS EN314-1 and section 4 of BS EN 314-2. Bonding properties on middle veneer are tested and evaluated accordingly, and the sample specimens are subjected to pre-treatments according to procedures outlined in section 5.1.3 of BS EN314-1 before receiving shear strength test). these projects’test results are all pass.

Test photo and our certificate images:

Our Service

1.Technical support by Phone, E-mail, Skype, What’sapp, MSN around the clock.

2.Friendly English operation manual, easy to understand.

3.Payment Terms:L/C,T/T,D/P,D/A,Western union.

4.MOQ:AS Requirement.

5.Choose the cheapest and safest shipping company to save the cost.

6.Track the order until you get the goods.

7.Protection of your sales area, ideas of design and all your private information.

PRODUCT LIST

![]()

Vietnam Plywood

Plywood

-

Plywood

-

Commercial Plywood

-

Fancy Plywood

-

UV Plywood

-

Film Faced Plywood

-

Marine Plywood

-

HPL

-

Bamboo Plywood

-

Melamine Plywood

-

Flame Retardant Plywood